Recently a line to produce steel coils with galvanized coating has been put in operation at the Karaganda Steel Mills (Ispat Karmet). The new complex strikes as being one of the modern, versatile installations with state-of-the-art technology in CIS in the last decade and, undoubtedly, proves the potential of this industry in terms of fast and efficient modernization. It also reflects a strategy of the mills’ new owner, the LNM Group: to acquire unprofitable enterprises and revive them. In an interview kindly granted to Eurasian Metals N.K. Choudhary, the general director and CEO of Ispat Karmet, gave a detailed account of objectives and results of the Group’s operations in Kazakhstan.

«Our main task is to reach world standards of product quality and production efficiency», N. K. Choudhary said. «We need to raise our competitiveness in the international steel trade marked by the severest struggle for sales markets. In a situation like this it is simply impossible to survive having products of poor quality. The second important aspect is the quality of customer service. So as to give preference to your products customers should be able get them as soon as demanded. As for operating the Karaganda Steel Mills, we are trying to fully utilize available capacities. In 1995 Karaganda Steel Mills produced 2.1 million tons of rolled steel. This year we expect to do 3.8 million tons», he noted. «Our main task is to reach world standards of product quality and production efficiency», N. K. Choudhary said. «We need to raise our competitiveness in the international steel trade marked by the severest struggle for sales markets. In a situation like this it is simply impossible to survive having products of poor quality. The second important aspect is the quality of customer service. So as to give preference to your products customers should be able get them as soon as demanded. As for operating the Karaganda Steel Mills, we are trying to fully utilize available capacities. In 1995 Karaganda Steel Mills produced 2.1 million tons of rolled steel. This year we expect to do 3.8 million tons», he noted.

The LNM Group won a tender for privatizing the mills in November 1995. At the time of Kazakhstan’s independence the Karaganda Steel Mill (the enterprise’s common name Karmet literally means the Karaganda integrated metallurgical plant) was the most powerful enterprise in the republic. It made coke and chemical products, pig iron, steel and a wide range of steel products, including tin plate. Then, the well-known events happened in the former Soviet Union. The traditional market fell apart. Demand for steel in the newly created states plummeted. All this caused a catastrophic downfall of production at Karmet. If in 1992 it made 5.7 million tons of liquid steel, in 1995 the volume was just half. The lack of funds for repairs and reconstruction led to a significant degradation of metallurgical installations. Payments of wages to the personnel were often delayed for more than four months.

So, Karmet was really in bad shape, when it was acquired by the LNM Group, which has a reputation for effective management of privatized enterprises. And this reputation is based on its eagerness to meet customer requirements to a maximum extent possible. The integrated mill served as a base of forming the Ispat Karmet company and it immediately got down to reorganizing production, working out strategic plans, making investments and implementing programs of equipment repairs. The next important step in efforts to secure a steady operation of the integrated mill was the acquisition of a neighboring electric power station and coalmines in the Karaganda basin.

«Since we came here in 1995, considerable changes took place. Now the enterprise has two additional galvanizing lines. A lot of work was done to automate and computerize all systems, major environmental protection measures were taken so as to comply with international standards. In particular, a new gas cleaning installation was assembled. The equipment in all shops of the enterprise as well as in coal mines were modernized», N. K. Choudhary said.

The total investments by the LNM Group, including those made to acquire the integrated mill, coalmines, an electric power station and related infrastructure amounted to about $800M. Under the investment program over $400M were put just in the development of Ispat Karmet. An additional investment of over $580M is planned for the next five years.

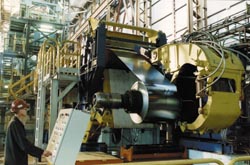

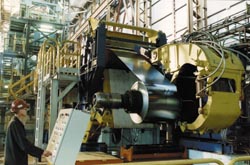

In the general director’s words, major investments were made in modernizing the production process, raising products’ quality and improving labor conditions. Thanks to investments the large projects were implemented. The pickling lines in the cold-rolling shop and sections for packaging finished products were among the first to be reconstructed. A hot-galvanizing and sheet-profiling shop was fully constructed. Its annual capacity exceeds 320,000 tons. It is noteworthy that the construction of this shop was started as far back as the 1980s. Works were dragging. A production block was built but there was no enough money for assembling equipment. Realizing the extreme importance of the project Ispat Karmet implemented it in less than three years and, then, started construction of another, more modern shop. The galvanizing line complete with the equipment manufactured by such prominent international companies as Danieli and Mitsubishi has been undergoing a technological running in since March 2002. But it is already making marketable products according to the international quality standards.

N. K. Choudhary particularly mentioned the packaging section constructed as a component of this line. In his words, today the packaging quality there is the best in the CIS. And it takes just a visit to the shop to get convinced that this is exactly so. Specially selected materials as well as careful packaging rule out any chance of products coming in contact with outdoor air or moisture regardless of transportation and storage conditions.

«We are always ready to ship products to consumers right on time. After products are delivered, we provide consumers with all possible assistance according to our special program», the head of Ispat Karmet stressed. And behind these words there is a really enormous work being done by the company. N. K. Choudhry himself sets an example sparing no time or efforts to travel and meet consumers of metals in any region with a potential market for the company’s products.

Ispat Karmet is using to the full extent the marketing experience of the LNM Group, which is well known in the business world. It had to open up sales markets practically anew and because of this the team of specialists faced plenty of nonstandard tasks. The geographical location of the mill was considered favorable, when consumers were nearby and the domestic demand for metals exceeded its production potential. Today almost 95 % of products are exported. Not a single metallurgical enterprise in the world operates in a situation like this. What is more, not a single one has to transport its products to the nearest sea port 4,500 km away paying high railroad tariffs.

|

Naval Kishore Choudhary (N.K.Choudhary)

Ispat Karmet’s General Director and CEO, 59 years old. Has been heading the integrated mill since January 2002. Graduated from the Kharagpur technological institute (India) in 1964, mining engineer, BA. Started the working career at the integrated iron and steel mill in Bhilai (India). Gained a rich professional experience working as a manager at India’s mines, large Indian and transnational companies. Went up the career ladder from being a manager to becoming the General Director of the company NALCO Aluminium. Joined the company INDAL as a Chief Executive heading the Utkal Mega Alumina project. In 1998 was appointed the company’s managing director for production. Introduced several production systems and formed joint management groups to renovate and restructure production. Before coming to Kazakhstan, was the chairman of the board of directors at Utkal Alumina International Ltd. for almost three years.

Studied at Harvard business school (Boston), universities in Hyderabad (India) and Seoul (Korea). At Ispat Karmet pays special attention to maintaining ties with consumers and tries to make the enterprise a competitive producer in the global market of metals.

| |

| |

|

But other problems facing the company’s managers are quite typical for large integrated iron & steel mills in Eastern Europe and the CIS. All of them encountered the need to implement structural transformations in view of changes in the traditional marketing system as well as tasks of raising competitiveness and adapting to process in the world steel market. There are also problems common to the world’s steel industry as a whole: economic recession in the West, persistent excess of capacities and, as result, aggravation of competition in the market of steel rolled stock. Nevertheless, in making investments in Kazakhstan’s metallurgical landscape, the LNM Group is sure of its success.

So, what are those factors that, in the opinion of Ispat Karmet’s head, contribute to an efficient metallurgical business?

First, the company is operating in a country exceptionally rich in mineral raw materials and energy resources. Ispat Karmet relies on the local raw materials base sufficient for providing steady supplies of high-quality iron ore, coal and other raw materials. The coal basin in the Karaganda region is world-renown. Its explored reserves of coking coal amount to 1.5 billion tons. Ore reserves are also considered large enough.

«We are developing three iron ore deposits, Lisakovskiy, Kentobe, Atasu, which, put together, provide up to 70 % of raw materials the mill needs. We receive coal from our own mines, which have an annual capacity of 9 million to 10 million tons. This coal is used for metallurgical production and generation of electric power», N. K. Choudhary noted. After the local thermoelectric power station became the company’s property, its capacity was raised from 70 Mw to 80 Mw up to almost 400 Mw. This is sufficient for the mill. What is more, a lot of other consumers in the Karaganda region are also using its heat and electric power supplies.

Ispat Karmet is a fully vertically integrated steel mill. The mill includes:

– Coke and by-product production;

– Sinter production;

– Blast-furnace shop;

– Steel-melting complex of converter, open-hearth and slab shops;

– Three sheet-rolling shops with finishing and packaging sections.

|

|

Another important advantage contributing to the business success in Kazakhstan is its people. As N. K. Choudhary said, «There are only 40 Indian specialists at the enterprise, who have an experience of working in Western economies. They provide competent assistance in marketing, finances and management. But most processes are handled by the local staff». The general director of Ispat Karmet described them as technically qualified specialists, who among other things show much interest in their work. His general conclusion sounded flattering: «We should recognize that today we are competitive in the market thanks to the good organization of work at our mill. The biggest value of our mill is its skilled personnel».

Finally, so as to succeed in business in a country that still lacks stable market institutions and democratic traditions the behavior of state structures is very important. Today this behavior is considered rather loyal to foreign capital. Foreign investors, including representatives of the LNM Group, highly appreciate the support by the Kazakhstan’s government and local authorities.

Taken together these factors result in making high-quality competitive metal products with the lowest prime cost in the world. That is why paraphrasing the well-known expression N. K. Choudhary called Ispat Karmet «a jewel in the LNM Group’s crown».

| Galvanizing line, constructed in March 2002 |

Feeling grateful to the country, which created conditions for a successful business, the company continues its investment activity. This time the renovation program is to embrace basic stages of the production cycle starting with the blast-furnace process. This work started with reconstructing Blast Furnace No. 3. Along with the overhauling, which is now close to completion, the project foresees increasing the furnace’s volume up to 3,200 cubic meters, renewing key joints and mounting automatic equipment made by Siemens. After that work will be done on the next blast furnace. The program is worked out in such a way that it permits to overhaul the shop’s all four furnaces without reducing their capacities for producing hot metal for converters.

In the opinion of N. K. Choudhary, at this stage one of the most important projects is a transition from the outdated technology of making steel ingots to a continuous casting, complete computerization of the production processes. «In the coming months we will start construction of Continuous Casting machine», he said. «This project will contribute to raising the market competitiveness of our products».

| Blast furnace 4 is one of the units to be reconstructed |

Recently the company’s new department of strategic planning was formed for analyzing and forecasting trends in sales markets as well as for working out a long-term plan of development for the next five years. Describing possible directions of investments during this period the general director of Ispat Karmet confidently said: «We will increase manufacture of galvanized products, move towards higher automation in our shops and develop the coal segment. It is necessary to raise the output of iron ore and improve the quality of concentrates and pellets». As N. K. Choudhary stressed, «most of these projects are being worked out in the mill’s laboratories as well as in our scientific research laboratories in the U.S.». Investments will be made in environmental protection, in training personnel and upgrading their qualification.

Commenting on a possibility of constructing a pipe plant in light of the desire of Kazakhstan’s government to develop the servicing sector of the oil industry, N. K. Choudhary said: «In principle, we have made a decision to start production of pipes. The technical and economic analysis is underway now. Sales markets and prospects for their development in the nearest 5 to 7 years are being examined. Basing on these data we will determine parameters of the required pipes as well as terms of stage-by-stage construction works. In two months we will choose a construction site. In the past we never dealt with pipe production. Today we are receiving help from our company’s specialists from Mexico. You may regard this project as kind of a present to Kazakhstan».

| Sheet-rolling shop 3 produces cold-rolled sheet steel and tinned plate of electrolytic tinning |

The story of Ispat Karmet’s activity would be incomplete, if it is limited to economic aspects only. The role of corporate policy in solving the region’s social problems should be noted as well.

If workers of the oil-and-gas sector are not counted, then, Ispat Karmet is the largest private employer in Kazakhstan. The company provides guaranteed jobs for over 52,000 metallurgists and miners. Besides, the integrated mill and coal mines engage a lot of small and medium business enterprises, which fulfill orders for equipment repairs, production of spare parts, transportation and other services. Districts of the city of Temirtau, where workers of the mill are residing, are provided with electricity, heat, water and other public utility services for the lowest tariffs in the region.

Under the agreement with the labor union the company takes upon itself a responsibility to look after workers’ social needs in different spheres of life: public utility at lowest and stable rates, medical care, assistance to retirees and low-income families, promotion of sports and arts, education and recreation of children. A list of such responsibilities may seem unending. However, one should take into account the mentality typical of the majority of the population in the post-Soviet space: workers are prepared rather to reconcile themselves with low wages than to refuse social privileges, which they grew accustomed to in the times of socialism.

| Ispat Karmet’s packaging quality is considered the best in the CIS |

In 2002 alone the company spent $3.6 million on sponsorship and charity. «We think that cooperating with the society is our duty», said N. K.Choudhary. Humanitarian projects of Ispat Karmet sit well with the scale of its business activity. The company built with its money an education and laboratory block of the Metallurgical institute in Temirtau and Aqua Park in Astana, Kazakhstan’s capital city. The coal department of Ispat Karmet constructed a fountain cascade in the Karaganda park. Besides, miners put a lot of energy in repairing a local stadium. The company can also boast of constructing Kazakhstan’s only alpine skiing course, a Muslim mosque in Karaganda and many other facilities that play an important role in the public life.

All this contributes to the atmosphere of close cooperation with the region’s population and authorities as well as to business development. «When the country is moving forward, it helps develop the industry», summed up N. K. Choudhary. «It is well known that an industry needs support on the part of a policy aimed at securing development and investments. There is a progressive government operating under the leadership of president Nazarbayev. Kazakhstan is confidently following the path of a market economy», he stressed.

|

back

back

«Our main task is to reach world standards of product quality and production efficiency», N. K. Choudhary said. «We need to raise our competitiveness in the international steel trade marked by the severest struggle for sales markets. In a situation like this it is simply impossible to survive having products of poor quality. The second important aspect is the quality of customer service. So as to give preference to your products customers should be able get them as soon as demanded. As for operating the Karaganda Steel Mills, we are trying to fully utilize available capacities. In 1995 Karaganda Steel Mills produced 2.1 million tons of rolled steel. This year we expect to do 3.8 million tons», he noted.

«Our main task is to reach world standards of product quality and production efficiency», N. K. Choudhary said. «We need to raise our competitiveness in the international steel trade marked by the severest struggle for sales markets. In a situation like this it is simply impossible to survive having products of poor quality. The second important aspect is the quality of customer service. So as to give preference to your products customers should be able get them as soon as demanded. As for operating the Karaganda Steel Mills, we are trying to fully utilize available capacities. In 1995 Karaganda Steel Mills produced 2.1 million tons of rolled steel. This year we expect to do 3.8 million tons», he noted.