Almaz Ibragimov

President, JSC Kazakhstan Aluminum

Basic products of Pavlodar Aluminum Plant:

– Extra-quality alumina (G-OO), output – 1. 2 million tons p.a.

– High-purity metallic gallium, extra-quality (6N and 7N), output – 20 tons p.a.

– Industrial aluminum sulphate,

I grade, output – more than 65 thousand tons p.a.

The joint-stock company Aluminum of Kazakhstan was founded in 1996 on the basis of Pavlodar Aluminum Plant. The company includes five enterprises and employs more than 11 thousand people. Apart from an aluminum plant, the company includes Torgaiskoye and Krasnooctyabrskoye Bauxite Mine Groups, lime mine Keregetas and Pavlodar Thermal Power Station No 1. They represent a single technological complex. The availability of a raw material base and an own source of power enables the company to organise efficient production processes and produce products with relatively low costs. The joint-stock company Aluminum of Kazakhstan was founded in 1996 on the basis of Pavlodar Aluminum Plant. The company includes five enterprises and employs more than 11 thousand people. Apart from an aluminum plant, the company includes Torgaiskoye and Krasnooctyabrskoye Bauxite Mine Groups, lime mine Keregetas and Pavlodar Thermal Power Station No 1. They represent a single technological complex. The availability of a raw material base and an own source of power enables the company to organise efficient production processes and produce products with relatively low costs.

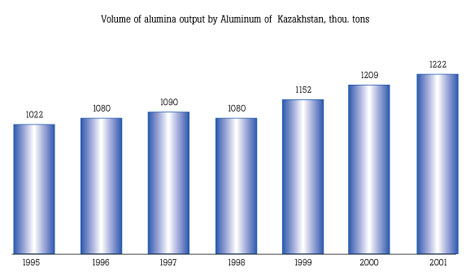

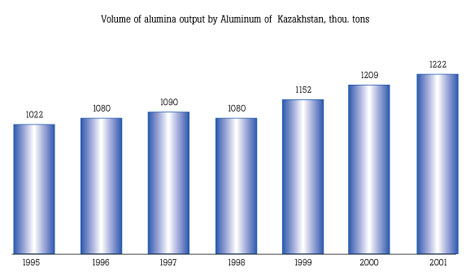

The main product of the company is alumina, which is supplied to Russia and China for processing.

The fact is that a metal production technology was not initially envisaged at Pavlodar Aluminum Plant, which was put into operation in 1964. However, today, the company management plans to build an electrolysis facility in Pavlodar.

Bauxite processing is carried out in accordance with a progressively combined Bayer-agglomeration scheme. Alumina is produced by the company’s core plants: a dressing workshop, a hydrometallurgical workshop and an agglomeration shop. During the six months of 2002, the company produced 655 thousand tons of alumina, which is by 11 % more than for the similar period of the previous year.

In addition, Aluminum of Kazakhstan produces gallium, a metal which is used by knowledge-intensive sectors, such as electronic engineering, helioenergetics and laser technique. Gallium is supplied to EC countries, the United States and Japan.

Another product is aluminum sulphate, a high-efficiency coagulant for drinking water purification and industrial and household effluents treatment. The Company fully meets Kazakhstan’s needs and supplies aluminum sulphate to Russia.

| Pavlodar Aluminum Plant. Calciner at the hydrometallurgical shop |

In 2000, the company approved a five-year comprehensive technical reequipment programme, which envisages an increase in alumina production up to 1.5 million tons by 2005, which significantly exceeds the approved designed capacity of the Pavlodar Plant (1 million 50 thousand tons p.a.). During the first two years, the volume of investments in these areas exceeded $80 million. At the start of 2002, the plant put into operation an additional, fifth, calcination furnace with the capacity of 300 thousand tons of alumina p.a.

The total value of the technical reequipment programme is $99 million, out of which $19 million will be invested in environmental measures. It is noteworthy, that Aluminum of Kazakhstan pays much attention to ecological security. To coordinate the work in the area, the company created a department for power supply, environment and labour protection. Environmental measures are annually developed in cooperation with the Regional Environmental Department. The plant is installing modern dust-catching facilities on those sites, which have basic contamination sources (agglomeration and calcination furnaces). In 2001, the company invested $3.6 million in environmental measures.

The territory of the company is a real oasis (45 thousand trees and bushes, 21 hectares are swarded, and 9 thousand m2 are occupied by flower gardens). During the last three years, the company have been actively renewing vegetation resources. By expanding the green belt area we, first of all, pursue environmental goals. The green belt and environmental equipment are equally important.

The company operates a system of analytical control of initial stock, semi-products and finished products. The company carries out all necessary procedures for obtaining ISO 9000 certificate of conformity.

The company is successfully winning recognition of the international community. In April 2002, in Brussels there was held the tenth jubilee session of Euro Market Center (EMRC). More than 100 enterprises and representatives of various governments took part in this event, including specialists from Deutsche Bank and European Bank for Reconstruction and Development. At this session, Aluminum of Kazakhstan, as a member of EMRC Club, was awarded a honorary reward of this reputable organisation for achievements in management, quality, business and consolidation of the image in the European market.

| Pavlodar Aluminum Plant. Chemical metallurgy shop |

Aluminum of Kazakhstan subdivisions are also awarded international organisations’ rewards. In 1999, Keregetas Lime Mine was awarded a Platinum Quality Star by World Quality Commitment. In 2000, Torgaiskoye Bauxite Mine Group received a Golden Quality Star from International Star Award Geneva. Aluminum of Kazakhstan makes significant investments in charities and sponsorship. In 2001 only, $3.8 million were allocated for these purposes. The company is a sponsor of Irtysh Football Club, Samal Rehabilitation Center for children, a mosque in the settlement of Maikain of the Pavlodar Region, schools and many other organisations that need financial support.

As a member of Eurasian Industrial Association (EIA), Aluminum of Kazakhstan meets its requirements and implements a programme on vocational, technical training and education of management and operating personnel. From 10 to 30 % of employees attend retraining courses at EIA enterprises. The cost of such training amounts to 1 % of production expenses. In 2001, Aluminum of Kazakhstan organized retraining programmes for more than 3 thousand people.

| SUPPORT OF SMALL BUSINESSES |

The development of small business at enterprises of the Eurasian Industrial Association is directly connected with the implementation of Kazakhstan�s state programme on import substitution. The work is carried out in two directions: support of Kazakh enterprises and production of import substitution products by own means. Last year, the Association�s enterprises bought from Kazakh producers equipment and materials to the amount of more than 9 billion tenge, which exceeds initial expectations by more than 80%. This is almost a fifth part of the overall republican programme.

Today, traditional deliveries of mining equipment, castings, low-voltage equipment and spare parts are redirected to Kazakhstan. We witness successful cooperation with Vostokmashzavod and Promservice from Eastern Kazakhstan, Electroapparat (Almaty), company Zima (Zhambyl), etc. For example, on the initiative Donskoy Mining and Dressing Plant, Vostokmashzavod started to produce scraper winches, wagons and cars.

A lot of work is carried out to cut import of basic technological raw materials. Last year, Ferrochrome JSC refused from Russian lime deliveries, and this year the enterprise plans to fully transfer to quartzite of Ereymentaus field. The enterprise works under a programme planned for completion by 2005. The programme�s dynamics is the following: this year $11.88 million will be allocated for import substitution, next year – $12.2 million, in 2004 – $12.6 million and in 2005 – $13.5.

Within the Small and Medium Business Support Programme Aksu Ferroalloys Plant closely cooperates with local enterprises, such as Safia (meat and milk production) and Aksu company Ak Bulak (mineral water production). The enterprise supplies them with heat and power, assists in the building of greenhouses with the total area of 15 thousand m2, and in return receives products for the canteen.

|

|

back

back

The joint-stock company Aluminum of Kazakhstan was founded in 1996 on the basis of Pavlodar Aluminum Plant. The company includes five enterprises and employs more than 11 thousand people. Apart from an aluminum plant, the company includes Torgaiskoye and Krasnooctyabrskoye Bauxite Mine Groups, lime mine Keregetas and Pavlodar Thermal Power Station No 1. They represent a single technological complex. The availability of a raw material base and an own source of power enables the company to organise efficient production processes and produce products with relatively low costs.

The joint-stock company Aluminum of Kazakhstan was founded in 1996 on the basis of Pavlodar Aluminum Plant. The company includes five enterprises and employs more than 11 thousand people. Apart from an aluminum plant, the company includes Torgaiskoye and Krasnooctyabrskoye Bauxite Mine Groups, lime mine Keregetas and Pavlodar Thermal Power Station No 1. They represent a single technological complex. The availability of a raw material base and an own source of power enables the company to organise efficient production processes and produce products with relatively low costs.