A broad-scale reorganisation of the lead-zinc industry in Eastern Kazakhstan was undertaken in the mid 1990s. At that time, the government made a strategically wise decision to consolidate the metal mining and metallurgical business. In January 1997, there appeared a new enterprise, Kazzinc JSC, and already in June, this company had a strategic investor. Kazzinc’s controlling interest was purchased by Kazasturzinc, who attracted Glencore International, a recognised leader in non-ferrous metal production, as a source of finance. A broad-scale reorganisation of the lead-zinc industry in Eastern Kazakhstan was undertaken in the mid 1990s. At that time, the government made a strategically wise decision to consolidate the metal mining and metallurgical business. In January 1997, there appeared a new enterprise, Kazzinc JSC, and already in June, this company had a strategic investor. Kazzinc’s controlling interest was purchased by Kazasturzinc, who attracted Glencore International, a recognised leader in non-ferrous metal production, as a source of finance.

Kazzinc JSC unites four industrial complexes: Leninogorsky (currently – Riddersky) Mining-and-Metallurgical Integrated Plant, Zyryanovsky Mine & Concentrator, Ust-Kamenogorsky Metallurgical and Bukhtarminsky Energy Complexes. Later they were supplemented by Tekeliysky Mine & Concentrator, and in January 1998, by Tekeliysky Energy Complex.

Kazzinc management determined several stages in the development of the new company. The priority direction for 1998 was the construction of Maleevsky Mine, which was associated with the expected future development of the company.

Ores of Maleevsky Deposit contain more non-ferrous metals if compared with other sites, and the volume of explored reserves allows for production at the level of the existing need in raw products during 25 –30 years.

The project was considered in detail with account of the world-wide experience in the mining sector. The key task was to ensure full-scale financial investments and a quick return on loans, which stipulated extremely tight time limits. In June 2000, the mine was put into operation. Its equipment meets international standards. Driving and extraction of ore is carried out with up-to-date mining self-propelled machines of leading producers.

Maleevsky Mine operates within Zyryanovsky Mine & Concentrator. The work covers the construction of a delf and reequipment of a concentrating mill. The completion of this work enables the enterprise to increase the volume of ore extraction and processing from 1.5 million tons (1997) to 2 650 thousand tons p.a. and bring the commodity output level to $175 million.

Riddersky Mine & Concentrator steadily increases production output. The plant includes 3 delfs and a concentrating mill. Kazzinc JSC allocated necessary funds for the development of this production facility: new equipment and technological materials were purchased, which allowed to improve the production and concentration technology. During the first year of operation in the company, the volume of produced ore increased by 20 %, and the commodity product output increased by 17 %.

After completing the construction of Maleevsky Mine, Kazzinc started to increase its metallurgical treatment facilities, i.e. to upgrade the lead and zinc plants in Ust-Kamenogorsk and Ridder, and divisions engaged in rare and noble metals production. Together they form the largest in the CIS lead and zinc production complex. An important event for Ust-Kamenogorsky Zinc Plant was the putting into operation of the 3rd series of zinc electrolysis with centralised air cooling of electrolyte in cooling stacks. This technology was for the first time used by zinc plants in the CIS. Ridder metallurgists managed not only to restore the lost production volumes, but, due to a number of operations, to exceed the design capacity of the enterprise.

| Maleevsky mine |

The inclusion in the JSC became a turning point for the repair and engineering plant (currently – Riddersky Repair & Engineering Plant). Within a short time limit, the workshops’ structure was optimised and new products were developed. Today, a plant, which only 5 years ago had no orders and set wages for staff, produces up to 40 items. The enterprise produces mine electromotives, cars for transportation of ore from mine tunnels, scraper winches, flotation machines of various modifications, bull rods, etc. These items are well competitive to replace imported analogues. Today, Kazzinc, which invested money in the reequipment of idle facilities, may significantly cut down expenses relating to the acquisition of expensive equipment, spare parts and technological materials for its enterprises. At the same time, the plant also executes orders for other mining-and-metallurgical enterprises of Kazakhstan.

Another structural subdivision of Kazzinc JSC is Bukhtarminsky Hydroenergy Complex, which supplies power to all production companies, continues to meet load demands and implement regulatory, reservation and other functions for the energy system of Kazakhstan.

| Kazzinc JSC output is 6 million tons p.a. Mining and concentrating production is represented by several delfs (Maleevsky, Tishinsky, Grekhovsky, Altaisky, Tekeliysky) and three concentrators. |

|

The appearance of a hydroelectric plant in the structure of the metallurgical company was not accidental. In the period of economic recession of the mid 1990s, financial flows from energy consumers actually ceased. For this reason the enterprise has to suspend planned repairs of power equipment, whose wear rapidly sank to the threshold level (especially the impulse wheels of hydraulic turbines). The situation became critical. When Kazzinc acquired the assets of Bukhtarminsky hydroelectric plant, it carried out an overall revision of the equipment and developed a schedule of repair and technical reequipment work up to 2005. The amount to be allocated for these purposes equals to $15 million. This modernisation allowed to increase the level of reliability of the station and thereby create a reliable source of power for Kazzinc enterprises and other consumers in this industrial region.

| Pit, Tishinsky mine |

Kazzinc assists the government of the Republic of Kazakhstan in implementing a policy aimed at the support of social activity in little towns, reduction of social strain and creation of the environment for economic growth in the depressive regions. The shareholders, who, in November 1997, voted for the inclusion of a loss-making enterprise (Tekeliysky Lead and Zinc Plant) in the company, were guided by this consideration. During the recent 5 years, this mine and concentrator has been handling outbalance ores of Tekeliysky Deposit in constantly aggravating mining and geological conditions. This results in high costs of ore extraction and processing.

Notwithstanding a sufficient logistic support of the existing production processes and significant financial expenses relating to technical reequipment, the plant remains unprofitable and generates direct losses in the amount of $3.5 million.

| Bukhtarminskaya hydroelectric station is the main source of electric power for Kazzinc JSC |

Considering the exclusive importance of this plant for Tekely and its habitants, the company undertook unprecedented actions. At the start of 2002, there was approved a social and humanitarian concept of the future development of the company. In the nearest future, it is planned to create economically efficient facilities, oriented to production of foodstuffs, garment, construction materials and other mass products. During two years, the company will allocate more that $6 million for the implementation of this programme. By the end of this year, new production facilities will employ 300 former workers of Tekeliysky Mine & Concentrator.

Kazzinc JSC’s structure includes:

– Two zinc plants with the output of 250 thousand tons of zinc p.a. (the 7th position in the world);

– A lead plant with the output of 140 thousand tons of lead from raw ores;

– Refinery facility with the output of more than 7 tons of gold and 300 tons of silver p.a. |

|

Since its foundation, Kazzinc JSC has laid stress on ecological safety of production and undertakes measures aimed at the rehabilitation of the environment. The semicentennial metallurgical activity in this region exercised an adverse impact in the form of accumulated production wastes, contamination of soil and water bodies. Today, the ecological environment around Kazzinc’s metallurgical plants and mine & concentrators is better. This is a result of a set of the below stated actions.

Upgrading of the dust-catching plants. A new purification system was installed, which allowed to meet the prescribed sanitary standards. | Riddersky repair and mechanics works |

A new storage of arsenic wastes with high reliability was built, which excludes their entry in the environment. A number of protective measures were implemented in the course of reconstruction of vitriol workshops. Mine water treatment facilities were installed at Maleevsky Mine. A concentration mill of Zyryanovsky Mine&Concentrator started to apply the dichromate method of complex ore concentration. A lead plant in Ust-Kamenogorsk started to construct a new vitriol facility using a wet-gas purification technology developed by Haldor Topsoe, Denmark. Kazzinc JSC allocated more than 17 million Euro for this project.

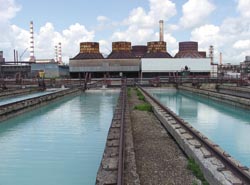

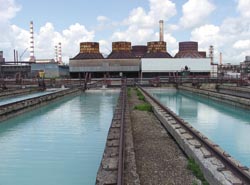

| Cleaning installations, Ust-Kamenogorsk metallurgical platform |

Kazzinc JSC, for the first time in the metallurgical practice of Kazakhstan, implemented the JDEdwards management computer system. This enables company managers to get real-time information on the situation on all production sites.

In 2001, Kazzinc started to implement a quality management system based on ISO 9000. The company is planning to obtain a certificate of conformity to this system in 2003.

The work of non-ferrous enterprises exercises a tremendous impact on the state and development of the social infrastructure of Eastern Kazakhstan, a region, in which this industry prevails.  | Maleevsky mine, ore loading |

Kazzinc JSC is a leader in terms of production volumes and number of employees: company enterprises employ approximately 20 thousand people. Considering its responsibility for the life of the existing and future generations of this region, Kazzinc has under its care a lot of social assets, built in the previous years. Kazzinc supports Zyryanovsky and Riddersky recreation centers – their creative teams are well known outside Kazakhstan. The company finances summer health camps for children of miners and metallurgists and recreation camps for employees and their families.  | Concentrating mill, Kazzinc JSC |

The company maintains a traditional system of occupational disease prevention: specially organised institutions (preventoriums) have necessary conditions for relaxation of employees and diagnostics; modern methods of treatment are used.

Kazzinc takes care of the retired workers. They are provided financial aid and other forms of social support through a network of veterans’ organisations in all of the cities, in which Kazzinc JSC has production facilities.

| Kazzinc-Torpedo, the best hockey team of Kazakhstan, successfully participates in the Russian major league’s matches |

The company obeys most traditions, created by the former management of metallurgical enterprises. For example, mass recreative sports are very popular, such as Akim’s Olympics (akim is a local governor) and regional and republican competitions. The financial and organisational support of these events is part of Kazzinc JSC’s social policy. The company is a sponsor of the Kazzinc-Torpedo hockey team, which is the pride of the Kazakh sport. The team is the leader of the national championship, the winner of gold and bronze medals of the major league championship of Russia in 2001–2002 and successfully participates in international competitions. The company maintains a hockey school for children in Ust-Kamenogorsk and invested more than $3 million in the capital reconstruction of the local sports palace with an ice arena.

The recent 5 years proved that the expectations of a qualitative growth as a result of a merger of related companies’ assets paid their way. Kazzinc JSC’s potential is sufficiently high. The company is one of the flagships of the Kazakh economy. Its employees are interested in achieving the stated goals and want to see their company strong and prosperous.

|

back

back

A broad-scale reorganisation of the lead-zinc industry in Eastern Kazakhstan was undertaken in the mid 1990s. At that time, the government made a strategically wise decision to consolidate the metal mining and metallurgical business. In January 1997, there appeared a new enterprise, Kazzinc JSC, and already in June, this company had a strategic investor. Kazzinc’s controlling interest was purchased by Kazasturzinc, who attracted Glencore International, a recognised leader in non-ferrous metal production, as a source of finance.

A broad-scale reorganisation of the lead-zinc industry in Eastern Kazakhstan was undertaken in the mid 1990s. At that time, the government made a strategically wise decision to consolidate the metal mining and metallurgical business. In January 1997, there appeared a new enterprise, Kazzinc JSC, and already in June, this company had a strategic investor. Kazzinc’s controlling interest was purchased by Kazasturzinc, who attracted Glencore International, a recognised leader in non-ferrous metal production, as a source of finance.