|

| Magazine |

|

| About |

|

| SUMMIT |

|

| Contacts |

|

| Home |

|

|

|

|

|

| |

|

|

|

| #3' 2003 |

print version |

|

|

HIGH TECHNOLOGIES FROM RUSSIA |

|

Valery Karmachev

President, SpetsAtomMontazh JSC

Valery Karmachev,

President, SpetsAtomMontazh JSC |

|

rom its very birth Russia’s nuclear power complex has been developing in close cooperation with other energy, electrical and hydraulic engineering industries. Only a few are aware that the organization, which built the first Soviet metallic uranium-producing plant in the city of Electrostal near Moscow, had its roots in hydraulic engineering. Before World War II the Volgostroy construction association started building the Uglichskaya, Rybinskaya and Shekninskaya hydroelectric stations and in the fall of 1945, a few weeks after the atomic explosion in Hiroshima, Volgostroy’s Noginsk division (operating in that area) began construction and assembly works in Electrostal. And there was nothing unusual about this. Many production and scientific research facilities of the nuclear power industry were power-intensive. That is why they were built near large hydroelectric stations. For example, today’s Electro-KhimPribor, the integrated multi-business mill (also known as Sverdlovsk-45 or Lesnoy), was originally an enterprise of electromagnetic separation of isotopes, which was built in 1947 near the Shirokovskaya hydroelectric station in the Urals and the complex in Dubna, which used power from the Ivankovsky hydroelectric center on the Volga-river for its accelerators.

But in a short time the nuclear power industry itself became the strong, stable and effective producer of energy resources. Incorporated in the Ministry of Middle-Sized Machinery or MinSredMash (now the Russian Ministry for Atomic Energy or MinAtom) industrial, scientific, construction-and-assembly enterprises and related organizations gained a unique experience of producing and using energy resources, creating energy-effective and energy-saving systems, constructing and operating water-resource facilities.

The world’s first water-desalinating plant with the BN-350 fast reactor built in the early 1970s on the deserted and waterless Mangyshlak Peninsula is one of the best-known instances of the successful cooperation between nuclear scientists, electrical engineers and hydraulic system builders of MinSredMash. For over 25 years this complex provided uninterrupted supplies of drinking water and electric power to the gigantic Prikaspiysky integrated mining-and-metallurgical mill (now the Mangyshlak integrated nuclear power mill in Aktau, Kazakhstan) and several cities with population of about 300,000 inhabitants.

Unique for both the technological potential and the level of responsibility the system created by MinSredMash, which includes scientific research centers and institutes, design offices, construction-and-assembly organizations and series production plants, carries out a complete cycle of works from conducting fundamental research to preparing the operation of constructed production facilities. For six decades all construction-and-assembly works at sites of nuclear science and technology, the nuclear weapons complex and civil nuclear energy industry, at experimental and industrial electrophysical installations, at construction sites of nuclear reactors and power plants, at water-desalinating complexes, test desks, accelerators and thermal power stations were carried out by specialists of a state organization, of which SpetsAtom-Montazh JSC, has become the successor.

During Russia’s economic crisis in the 1990s, when investment and construction activities declined and major orders were not forthcoming, many similar structures in other industries after having lost their working capital broke up into small weak firms. SpetsAtom-Montazh, on the contrary, retained its single technological complex, skilled specialists with a unique experience in all kinds of construction-and-assembly and assembly-and-adjustment works as well as the engineering and production potential of over 30 enterprises, which are our company’s shareholders.

Today organizations incorporated in SpetsAtomMontazh fulfill orders not only from the nuclear power industry (the Rostovskaya and Kalininskaya nuclear power plants, complex 348 of the Russian scientific center Kurchatov’s Institute, other construction sites of the Ministry for Atomic Energy). Our customers include Gazprom, oil, petrochemical and metallurgical companies, enterprises of microelectronics and instrument-making as well as practically all other industries.

SpetsAtomMontazh has customers in Germany, Finland, Bulgaria, China and India, in countries of Asia and the Middle East. Our specialists worked at the Tomsk chemicals plant adjusting polyethylene production equipment of Italian, German, Japanese and Czech companies according to their designs.

The core of the concern SpetsAtomMontazh is formed by 12 construction-and-assembly enterprises of MinAtom’s system: the production assembly-and-construction enterprise Electron (Novosibirsk), EnergoSpetsMontazh (Moscow), PromElectroMontazh (Moscow), MosPromTechMontazh (Moscow), KONETAM (Electrostal), UralGidroMontazh (Ozersk, also known as Chelyabinsk-65), SpetsTeploKhimMontazh (Seversk, also known as Tomsk-7), TeploKor (Moscow), PromStalKonstruktsiya (Novosibirsk), Glazovsky KhimMash Zavod (Udmurtia), GidroMontazh Trust (Selyagino). These enterprises have different backgrounds and specialization. And precisely this gives Spets-AtomMontazh the flexibility, mobility, the ability to accomplish varied and original engineering tasks with high quality and reliability.

SpetsAtomMontazh JSC with Russia’s MinAtom

Phone: (095) 239-4500

Fax: (095) 239-4567

|

ELECTRON

By the government’s special decision the KhimElectroMontazh Trust (the predecessor of Electron) set up in 1956 was to do wiring at sites of the nuclear power complex stretching from the Urals to the Far East. In 1992 KhimElectroMontazh was transformed into the joint-stock company Electron Proizvodstvennoye Montazhno-Stroitelnoe Predpriyatiye. Electron’s managing structures are located in Novosibirsk, the business, industrial and scientific center of Western Siberia. Its main production capacities are also in Siberia. They are 9 construction-and-assembly departments, 3 wiring-producing mills, department of mechanization and motor vehicle transport, start-and-adjustment department, trading house with its own approach lines and large modern warehousing, construction-and-assembly laboratory and other self-dependent subdivisions.

Electron JSC

Phone: (3832) 761-331

Fax: (3832) 760-712, 762-076

|

ENERGOSPETSMONTAZH

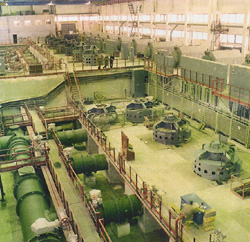

Moscow-based EnergoSpetsMontazh JSC specializes in making and assembling structures, equipment and articles for all energy industries. Its specialists implement complex assembling of nuclear power installations, high- and low-capacity reactors, power blocks of nuclear and thermal power plants as well as heat exchange, turbine and other equipment, pipelines, building metalwork frames.

EnergoSpetsMontazh JSC

Phone: (095) 160-8903

Fax: (095) 169-4225

|

PROMELECTROMONTAZH

Moscow-based PromElectroMontazh JSC is a successor to a construction-and-assembly production association of the same name set up in 1960 to carry out the whole complex of design, construction-and-assembly as well as start-and-adjustment works at power facilities including their social infrastructure. Today, it consists of assembling, design and start-and-adjustment subdivisions, the center of production-and-technological assemblage (CPTA), industrial center and certification center. PromElectroMontazh has a well-equipped production base, instrument pool, appropriate machinery, tools and devices.

PromElectroMontazh JSC

Phone: (095) 160-2710, 169-5275

Fax: (095) 160-1313

|

MOSPROMTECHMONTAZH

MosPromTechMontazh JSC is one of the oldest construction-and-assembly enterprises in energy. It is a predecessor of All-Union Trust 1, which was formed by the 11.27.46.order of the USSR government within the Ministry of Electric Power Stations and Electrical Industry authorizing to assemble scientific research installations of atomics physics and facilities of nuclear energy. Already in 1949 the Trust successfully completed works to assemble a synchrocyclotron complex in Dubna, the birthplace of the civil nuclear science in the USSR. There was no similar accelerator then anywhere in the world. Its next project was the E20 industrial cyclotron in the Urals. In 1957 the Trust was transferred to MinSredMash. Its personnel assembled accelerators with all available technological systems (vacuum, water-cooling, control, etc.) at the Moscow Institute of theoretical and experimental physics, in Yerevan and Protvino near Moscow. In 1961 the IRT-2000 reactor (model research reactor) was successfully put into operation in Riga (Latvia) and that led to a new direction of assembling works. In a short time there were 5 research reactors put in operation into Minsk, Kiev and other cities. The unique experience of assembling and adjusting complex systems for controlling and protecting energy processes in reactors allowed the Trust’s specialists to effectively carry out works at the Leningradskaya and Ignalinskaya nuclear power plants.

MosPromTechMontazh JSC

Phone: (095) 288-9221, 284-4200

Fax: (095) 284-4348

|

KONATEM

The head office of the concern KONATEM (KonversAtomEnergoMontazh) is located in the city of Electrostal near Moscow, on the site where the first Soviet metallic uranium was produced. The multi-functional concern includes 3 joint ventures in the neighboring countries, 16 joint stock and closed stock companies, branches and offices in several Russian regions and abroad. The major task of this organization, which was formed as far back as 1945, at the time the Soviet nuclear industry was established, is to assemble nuclear and thermal energy as well as chemical installations, manufacture and assemble building structures, systems of ventilation and air conditioning, nonstandard high-complexity equipment, external and internal pipelines.

Under its conversion programs KONATEM builds, supplies, assembles and delivers on the turnkey basis gasoline stations, gas pipelines and gas-distribution stations, boiler-houses and heat centers, waste disposal plants.

The concern’s specialists participated in building the first nuclear power plant in Obninsk as well as the Leningradskaya and Ignalinskaya nuclear power plants, integrated mining-and-chemicals mills in Krasnokamensk, Zheltye Vody (Ukraine) Stepnogorsk (Kazakhstan), Europe’s most powerful Kirovo-Chepetsky integrated chemical mill and the world’s largest Lebedinsky integrated mining-and-concentrating iron ore mill.

Concern KONATEM JSC

Phone: (095) 702-0725

Fax: (095) 702-9070

|

URALGIDROMONTAZH

UralGidroMontazh JSC is of the same age as the Mayak integrated radiochemical mill and is based in the closed city of Ozersk (Chelyabinsk-65) in the southern Urals. At the end of 1947, when works on building Base-10 (future Ozersk) were underway, line office No.6 of the Hydromechanization Administration was set up. Thus, the history of UralGidroMontazh started. The successful operation of the first industrial reactor for producing metallic plutonium depended largely on reliability of water-supply systems and the work force. The reactor start-up took place on June 8, 1948 with academician I. Kurchatov being a chief operator and on June 19 the reactor reached its design capacity. Nowadays this day is marked as the official birthday of the Mayak production association. A small group of divers of legendary EPRON (the Expedition of Special Underwater Works) together with hydromechanics workers (-) developed into a still active enterprise for assembling and construction works.

UralGidroMontazh JSC

Phone: (35171) 79-303

Fax: (35171) 73-041

|

SPETSTEPLOKHIMMONTAZH

In January 1980 assembling-and-construction administration No.107 (MSU-107) of MinSredMash’s SpetsKhimMontazh Trust was set up in the closed city of Seversk (Tomsk-7) to implement special assembling and construction works at facilities of the Sibirsky integrated chemical plant. This organization became, in fact, a starting ground of today’s SpetsTeploKhimMontazh that developed from it. In the past decades hydromechanics specialists from Seversk gained a unique experience in installing thermal insulation, anticorrosive and refractory works at many facilities of the nuclear power complex and chemical production projects. They consist of the integrated mining-and-chemical mill in Zheleznogorsk (Krasnoyarsk-26), the electrochemical plant (ECZ) and artificial fiber plant (AFP) in Zelenogorsk (Krasnoyarsk-45), heat-and-power installations at the Tomsk integrated petrochemical plant. This is also a complex implementation of all anticorrosive, refractory and thermal insulation works at the Polypropylene, Methanol and EP-300 plants, which were built by designs under a follow-up by firms from the U.K., Germany, Italy, Czech Republic and Japan.

SpetsTeploKhimMontazh JSC

Phone: (3822) 777-932

Fax: (3822) 776-939

|

SPETSKHIMMONTAZH

By results of the VI All-Russian Contest for the best construction organization (2002) the close company SpetsKhimMontazh was placed among 150 leaders of Russia’s construction complex. The history of this Moscow-based organization goes back to specialized section No.6 of SpetsKhimMontazg Trust, which was formed in 1971 to implement anticorrosive, refractory lining and thermal insulation works as well as works to cover floors of the Leningradskaya nuclear plant (Sosnovy Bor) with elastron. With its patented material Special Layer-109 the enterprise won an international tender for the contract "Non-inflammable floor covering at the Kolskaya nuclear plant". Today ZAO SpetsKhimMontazh widely uses these technologies at facilities of not only nuclear power but also in other industries.

SpetsKhimMontazh JSC

Phone: (81269) 64-310

Fax: (81269) 64-846

|

TEPLOKOR

TeploKor JSC is a young and rapidly developing enterprise. Today, its branches operate in Obninsk, Zarechny (Penza-19), Dubna, Protvino, Volgodonsk. Formed in February 1995 in Moscow, TeploKor specializes in anticorrosive and chemical protection of construction structures and equipment as well as refractory lining and inner protective lining works, installation and adjustment of ventilation systems, making all types of thermal insulation, filled floors, soft roofs and assembling metal structures.

TeploKor JSC

Phone/Fax: 7 (0967) 746-468

|

PROMSTALKONSTRUKTSIYA

Novosibirsk’s PromStalKonstruktsiya JSC (till 1993 it was the PromStalKonstruktsiya Mill, which was set up in 1951) is a multi-field enterprise manufacturing structures and equipment for the construction industry including those for power facilities, lifting-transport machinery with any degree of complexity, pipelines, waste-disposal complexes.

The latest achievements of the enterprise are the manufacture of a unique legged conveyer with the carrying capacity of 1,400 tons designed to transport 1,000 MW nuclear reactors as well as large-diameter pipes for nuclear power plants, gantry cranes with the carrying capacity of 800 tons, uniform mountable-and-dismountable building structures, heat-insulated containers, stainless steel containers.

PromStalKonstruktsiya’s containers with capacities from 25 to 5,000 cubic meters can be used for storing and transporting water, oil products, any liquid, gaseous and friable deleterious substances.

PromStalKonstruktsiya JSC

Phone: (3832) 765-797

Fax: (3832) 743-221

|

GLAZOVSKY KHIMMASH ZAVOD

In three decades of the KhimMash plant’s operation in the city of Glazov (Udmurtia) its specialists perfectly mastered technologies of welding all engineering types of steels and alloys as well as the technology of high-precision mechanical processing of materials. The plant offers its services to make and assemble equipment for the construction, chemical, oil refining and other industries. It manufactures pipe-laying tractors and construction machinery, builds underground reservoirs for storing oil products and other liquids.

Glazovsky KhimMash Zavod JSC

Phone: (34141) 37-060

Fax: (34141) 36-440

E-mail: g-himmash@udmnet.ru

|

GIDROMONTAZH

In 1955 MinSredMash’s enterprise 646 Mailbox was formed in the Selyatino settlement near Moscow. Later it was named the GidroMontazh Trust. The enterprise got down to laying outside communications, drilling wells for water and various technological purposes, doing unwatering works, constructing trunk pipelines, inlets and outlets of water into river and sea basins. In addition to all this GidroMontazh started constructing different hydraulic engineering structures for nuclear power enterprises, establishing divers’ service for implementing technical underwater works, ensuring operation of a large number of hydraulic dredges and other machinery.

The pilot-production plant of GidroMontazh, which was commissioned in 1962, supplied equipment to the Novozemelsky and Semipalatinsk (Kazakhstan) nuclear ranges, nuclear power plant in Finland. Today, it manufactures metal structures, nonstandard equipment, complex items for industrial purposes.

GidroMontazh JSC

Phone: (095) 436-5510

Fax: (095) 720-4960

|

Organizations, which are incorporated in the concern SpetsAtomMontazh today, were originally created to accomplish those tasks that nobody tried to tackle before, successfully proving the high level of their professional skill. We therefore look to the future with confidence and are inviting all interested entities to join us in mutually beneficial cooperation.

|

|

|

|

|

|

current issue

previous issue

russian issue

|

|

back

back