Andrei Karunos

Following Russia’s power engineering and oil-and-gas industries as well as metallurgy, its mechanical engineering complex slowly but surely is getting out of the protracted crisis. According to the data from the Center for Macroeconomic Research BDO Unicon, rates of increase in output by the mechanical engineering and metalworking have exceeded 7 % a year making this sector one of the three leaders among the country’s main industries.

At the same time, by experts’ estimates, the production decline is still going on in the machine-tool building segment, one of the most important in the mechanical engineering industry. As machine-tool builders themselves believe, in 2003 the volume of making metal-cutting machine tools may decrease 15 % to 18 % more due to the falloff in demand by major consumers in the Russian market.

THE PAST THAT IS HARD TO LEAVE BEHIND

Most of Russian machine-tool building plants have a long and glorious history, significant achievements and they are rightfully proud of them. But traditions and leader’s ambitions restricted chances to make a proper choice that became real with the start of economic reforms. Probably, because of this the process of adapting to the market reality has dragged on becoming more painful than in other sectors.

Since the past is still having an impact on the activity of machine-tool builders, let us begin with the background.

The Krasny Proletary Plant is one of Russia’s oldest industrial enterprises. It was founded in 1857 in Moscow by the Bromley brothers, who were professional engineers. In the years of its operation the plant made 535,000 units of machine facilities. Machine tools with programmed numerical control (PNC) accounted for one tenth of this volume. Its traditional clients are enterprises of the mechanical engineering and metalworking industries, automakers and bearing plants, military industrial complex, chemical engineering, metallurgy. Machine tools with the Krasny Proletary brand are operating in 70 countries.

The history of the Kolomna Heavy Duty Machine Tools & Press (Kolomensky ZTS) dates back to 1914, when a factory of farming machines was set up near Moscow. Its production specialization changed many times over. During WWI this enterprise was producing artillery shells and on the eve of WWII it was repairing artillery systems. In May 1948 it made the first set of screw-cutting lathes. Later, the enterprise started producing other types of machine tools. The plant became one of the leaders of the machine-tool building industry: by the start of market reforms it made dozens of modified turning-and-boring and special lathes, boring and gear-hobbing machine tools, merry-go-round and grinding machine tools as well as quenching and woodworking machine tools, press-forging and other equipment. These products were exported to 48 countries. At present, the enterprise’s capital assets are consolidated under the Kolomenskie Stanky Ltd. brand. It offers customers machine tools for pipe machining, pressing equipment for pipe rolling mills, presses for punching automobile components. The plant also modernizes and repairs its clients’ equipment.

The Ryazan Machine Tool Plant (RSZ) is based in Ryazan, one of Russia’s oldest cities 200 km from Moscow. The plant started its operation after WWII, when production facilities to make lathes and automated lines were transferred from the Krasny Proletary Plant to this area. The enterprise began developing especially fast from 1959. Production capacities were being built up, new shops were being constructed. Export shipments were raised: they accounted for 20% to 25% of products’ total volume. At the beginning of the eighties it started making machine tools with PNC: their share exceeded 30 %. Since then, the enterprise have produced about 130,000 machine tools for different purposes.

Till 1990 the plant remained a rather narrowly specialized enterprise: it made machine tools for machining parts to definite size (up to 1,000 mm). Such were conditions of the planned economy: there was a clear-cut division between machine-tool builders by kinds (model types) of products and consumer industries. This legacy was obviously impeding the market entry. But, nevertheless, some enterprises did find their own way and even achieved certain success.

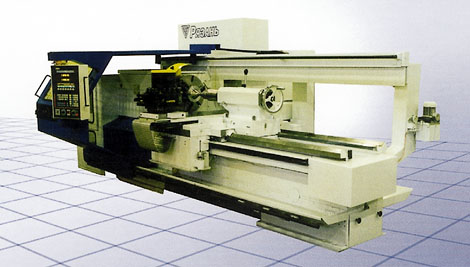

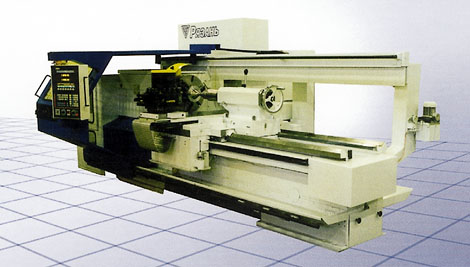

The Ryazan Machine Tool Plant. A bulging lathe (equipped with PNC from either Siemens or FAGOR) |

RSZ SEEKS "MONEY" NICHES

In 1991 the production volume at the Ryazan Machine Tool Plant started plummeting because of bankruptcies among its traditional customers. The enterprise’s management had to develop new market niches. According to RSZ’s chief designer Evgeny Kuznetsov, "the Ministry of Railways (MPS) was the first to accept our cooperation proposal". Ryazan machine-tool builders had no experience in making wheel-turning equipment and, thus, they began with simpler work: repairs of Polish and Ukrainian lathes, which were available at enterprises of MPS. In a year and a half they mastered modernizing them and, later, started making their own wheel-turning lathes, including those with PNC. Supplies to MPS reached 30 % of the total sales volume at RSZ and brought 50 % of profit in cash. At present, the plant makes about 20 types of lathes for MPS.

In the mid-nineties it started making equipment for repair enterprises of the oil-and-gas industry: for machining pipes, spherical and ball gate valves, stop valves. Orders from power engineering companies began coming in. Science intensive machine tools for processing components through cold rotating drawing are being purchased by the Khrunichev Scientific and Production Association (the aerospace complex), the Energo Scientific and Production Association (the defense complex) and a number of foreign companies.

Modernization of Russia’s metallurgy contributed to the increase in orders from enterprises of the steel industry and non-ferrous metallurgy as well as from pipe plants that are provided by RSZ with roll-turning machine tools and equipment for machining large spheres (both external and internal).

Cooperation with major mechanical engineering enterprises in Russia and CIS member countries became a special direction of activity: each of them has hundreds of machine tools from Ryazan. Evgeny Kuznetsov is convinced that repairs, modernization, replacement of machine tools with the new ones are a very serious business as well. For example, practically every month Moscow’s Salut (aircraft construction) gets from RSZ several new and modernized machine tools. The same principles provide the basis for cooperation with the Sumsky Power Equipment Plant (Ukraine).

The volume of export sales reaches 20 %. Evgeny Kuznetson defines the plant’s status in foreign markets as "solid average". Machine tools made by RSZ are shipped to the U.S., Great Britain, Australia, Turkey, Germany and other countries. As the chief designer believes, "by technical standards they do not yield to machine tools offered by leading world companies". He regards producers from Eastern Europe competitors as main competitors.

"Czech machine-tool builders are our serious rivals, they have about the same range of machine tools", says Kuznetsov. "There are practically no Polish machine tools left in the world market, the Bulgarian and Romanian ones have always been inferior to ours by their quality and they have cost less", he adds.

In order to raise the quality of its products the Ryazan Machine Tool Plant is cooperating with foreign suppliers of electrical equipment and electric motors. One of these partners is Siemens.

In the Russian market RSZ is quite capable of replacing leaders of the world machine-tool building. As an example, Evgeny Kuznetsov refers to the mobile equipment, which can be used for making very complicated components in small batches. "These machine tools are considered import substituting. It is impossible to buy them either in Japan or in any other country since their export shipments are forbidden because they can be used for making the most advanced arms", explains the chief designer.

In his turn, head of the marketing department at RSZ Anatoly Berkash draws attention to specifics of supplies. Ryazan machine-tool builders had to forget about producing large batches and switch to making one or two machine tools so as to satisfy, in fact, individual wishes of customers concerning their structural features. "We should feel the market. The whole world now does modular block assembling, unifies different components so as to assemble any machine tool using these modular blocks. We try to develop our plant in this direction as well", says Berkash.

RSZ’s management became one of the first in the Russian machine-tool building industry to initiate integration with allied enterprises. In order to combine engineering and marketing (through the Trading House) potentials the Ryazan Machine Tool Plant is to join the Egorievsky Gear-Hobbing Machine Tool Plant, Gorkovsky (Nizhegorodsky) Milling Machine Tool Plant and Berdichevsky Turning-and-Milling Semi-Automatic Machine Plant. It is quite possible that in time RSZ will become the core of a major mechanical engineering holding.

KRASNY PROLETARY IS BETTING ON TECHNOLOGIES

In recent years Krasny Proletary was increasing its production volumes by making, mainly, machine tools with PNC. In 2002 the share of the Moscow plant in the Russian market of such machine tools exceeded 40 %.

According to head of the marketing and sales department Vladimir Chony, Krasny Proletary is developing its production in three directions:

– making machine tools with PNC for serial and large-scale production; their output is based on the modular principle;

– making lathes with PNC for serial and small-scale production. In order to ensure compliance of these machine tools with up-to-date requirements concerning vibration and noise characteristics, basic components made of cast iron are replaced with the organic concrete ones that have a damping capacity 3.5 to 4 times higher;

– making especially precise machine tools for diamond turning. The highest standards of micron precision and reliability are applied to components machined at such machine tools. They are used by the automobile industry, aerospace complex, instrument-making industry, defense industry.

Krasny Proletary. The plant’s general view |

|

Recently, engineering services at Krasny Proletary have been integrated into an automated system of design and technological preparation of production facilities. It has let cut down time for designing new products by as much as 50 %, improve quality of design work and work on preparing production facilities. Today Krasny Proletary is ready to make and supply not just machine tools to its customer but the technology of making components or groups of components.

There is a center of complex technologies that makes it possible to solve many technological problems connected with creating single technological chains. The center has integrated three enterprises: Krasny Proletary, the Ivanovsky Heavy Machine-Tool Building Plant and StankoAgregat. The main task of the center is to analyze the situation and search for solutions acceptable in both technical and economic terms. The center consolidates makers of metalworking equipment and, at the same time, it is their structural division engaged in forward marketing. Enterprises that have founded the center have a solid experience of working with all sectors of the defense, aircraft, automobile, oil and gas industries as well as power mechanical engineering. Acting as a single executor, the center relieves customers of the necessity to get in touch with makers of this or that type of equipment and, in case of unavailability of home-made equivalents, it can find foreign sets.

PROTECTIONISM SHOULD NOT IMPEDE FREE COMPETITION

By definition, the machine-tool building industry is a base for implementing complex modernization in all industries, including the metallurgy. At the same time, despite the apparent trend toward overcoming the crisis and positive results of operations by some enterprises, there is no particularly evident growth in this sector.

Krasny Proletary. Machine shop No.2 |

|

Just like several years ago, experts consider insufficient investment volume and low demand in the domestic market to be the main problem. It is becoming harder for Russian machine-tool builders to participate in competition with leading world producers. Although they can offer machine tools of sufficiently high technological level, Russia’s machine-tool builders still do not have enough experience in advancing their products in markets and cannot provide customers with terms of business transaction and services similar to those that are offered by competitors. It is no accident that during discussions of Russia’s entry into the World Trade Organization the most skeptical remarks come from managers of mechanical engineering companies.

In their opinion, the State should provide the machine-tool building industry with additional support. Urgent requests of machine-tool builders include: optimizing tax policy, creating more attractive conditions for investments, reducing interest rate on credits, securing state orders.

In October Russia’s vice prime minister Boris Aleshkin promised the meeting of machine-tool builders to meet certain requests and, in particular, to reduce customs on imported components that are needed for making up-to-date machine tools. At the same time, according to general director of the foreign trading company StankoImport Sagadat Khabirov, an excessive support of one industry may hurt others. He believes that the state protectionism should not hold back development of the competitive environment, which is the best way to help raise the technological, production and engineering levels of Russia’s machine-tool building complex. Otherwise, says Khabirov, "in a few years we will not be able either to fly or to ride".

|

back

back