Yuri Adno

In recent years consolidation of assets became the most important tendency, which evolved into a characteristic feature of the metal business development in Russia and which resulted in forming large holding groups. Against such a background activities of the United Metallurgical Company (UMC) deserve special attention. In the opinion of analysts, this company possesses a considerable financial and production potential and pursues an up-to-date strategy. Therefore, it should be regarded as one of the most promising structures in Russian industry.

UMC JSC, a management company, was set up in 1992 and at present it incorporates metal producing plants, trading, transport and financial organizations as well as scientific research divisions. The group comprises about 20 enterprises with personnel totaling over 40,000 people. Among them are the two largest enterprises in the country’s pipe & tube industry, a by-product coke plants that put out a vast range of products, from pig iron to automotive springs and precision cold rolled steel strip. The UMC trading center is the sole commission and trade agent of all enterprises. Metallinvestbank JSB represents the financial structure.

The integration of these links into a single complex was carried out on the basis of long-established production and commercial ties. As UMC’ general director Anatoly Sedykh believes, «this factor as well as the full-fledged supply, production and marketing infrastructure, advanced management and integrated control system secure the group’s economic stability, its self-sufficiency and protection from the impact of unfavorable external forces».

«UMC is a management company for all the group of enterprises that it incorporates. In practical terms it means that plants have delegated management authority to «the center». Budget formation, marketing, supplies, planning and investments in modernization programs are centralized. The company and plants have the same managers, who are principal stockholders», notes Andrei Komarov, the chairman of UMC’ board of directors.

The past year was particularly successful for UMC. The volume of pipe production exceeded 1.5 million tons. For example, the output of its main product, large-diameter pipes for the oil-and-gas industry, increased by 30 %. The company’s turnover equaled almost $1 billion. And exactly this indicator puts UMC in the group of leaders of the Russian metals industry.

|

In the first half of 2002 the Vyksa Steel Works (VMZ) incorporated in UMC’ group of enterprises turned out 327,700 tons of pipe products, of which 112,600 tons fell on large-diameter pipes.

Production of water- and gas-supply pipes at VMZ in the first six months of this year amounted to 35,900 tons, by 15 % more as compared with the same period of last year.

This current year VMZ also produced 252 957 railroad car wheels, by 7.9 % more against the first half of 2001.

| |

| |

|

FROM PIG IRON TO RAILROAD CAR WHEELS

UMC’ product specialization is extensive: from traditional metal products (pig iron, steel billets, bars and sections, reinforcement, steel pipes of wide range) to such complicated products as automotive springs, railroad car wheels, mushy rolled products, precision steel band, ferrotitanium, etc.

UMC has one important peculiarity, which distinguishes it from other large holdings in Russian metals industry. The company incorporates enterprises, which either dominate the market or account for its considerable share by some products. For example, the Chusovskoy Iron and Steel Works (ChMZ) is among leading producers of marketable pig iron and, in addition, it accounts for over 45 % of the ferrovanadium market and 60% of the automotive spring market. The Vyksa Steel Works (VMZ) leads the industry by volumes of producing tubes and pipes for the oil-and-gas complex. At the same time VMZ is the largest supplier of railroad car wheels not only in Russia (62% of the market) but in the world as well. The Chelyabinsk Tube-Rolling Plant (ChTPZ) is the largest enterprise in the Russian tube & pipe industry producing pipes of the widest range. The Schelkovsky Steel Plant is the only enterprise in Russia and one of a few in the world, which turns out precision steel band for picture tubes.

The UMC structure has two production divisions, the steelmaking and pipe-producing ones. Each of them is based on the principles of maximum production cooperation and centralization of product marketing.

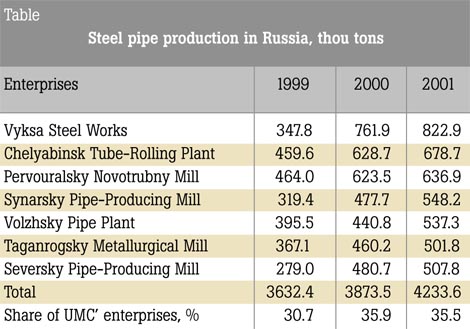

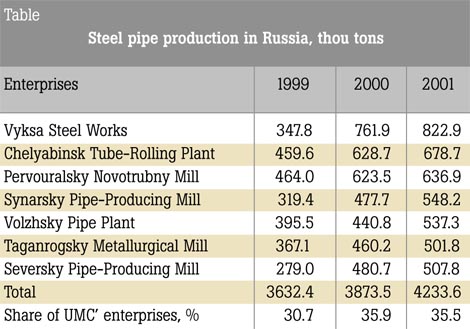

UMC’ pipe-producing complex represented by VMZ and ChTPZ accounts for 35.5 % of Russia’s steel pipe production volume. The share of these two plants in the Russian market of large-diameter pipes (over 480 mm) amounts to 80 %.

In Russia, only UMC’ enterprises turn out such products as seamless hot-rolled pipes with the diameter of 426 mm to 588 mm and wall thickness of over 32 mm, cold-reduced pipes with the diameter of over 120 mm, longitudinal-welded pipes with the diameter of 1020 mm and wall thickness of up to 32 mm, pipes for operating under temperatures of 60 degrees below zero as well as pipes for underwater pipelines. There is a quality control system, which is certified as corresponding to requirements of the API Spec Q1 standards. The quality of VMZ’ and ChTPZ’ products is confirmed by the API 5L certificate for mains gas-and-oil supply pipes and by the API 5CT certificate for casing tubes.

UMC supplies pipes for construction of main pipelines. They are produced from plate steel with mechanical properties and controled chemical composition, which provide necessary consumer characteristics, including increased corrosion and cold resistance. The company’s plants use progressive technologies of production and quality control: multi-arc flux welding of outside and inside seams with the use of modified power supply sources, combined methods of sizing pipe ends with the use of mechanical and hydraulic expanders, multi-stage system of step-by-step non-destructive seam control.

It is worth noting that UMC’ plants are also seeking to introduce progressive technological schemes. For example, they produce bimetallic pipes using stainless steel as well as welded casing tubes instead of seamless ones; this permits to reduce the steel intensity per casing string by 9 %. The plants mastered production of pipes with greater strength as well as casing pipes with increased tightness of threaded connection. Both plants, VMZ and ChTPZ, use the technology of applying outside multi-layered polyethylene and polypropylene coating on pipes for oil and gas pipelines.

The United Metallurgical Company is thoroughly analyzing requirements of potential customers. In 2001 UMC won 13 of 15 tenders for shipments of metal products to Russian consumers. At the same time the company is successfully realizing its export potential as well: last year volumes of shipping its products to markets in other countries increased by 30 %. On the whole, the export share amounts to 11 % of UMC’ sales volume. The company is exporting pipes, ferrovanadium, railroad car wheels, which are certified under the U.S. M-1003 standard. Trains with VMZ-produced railroad car wheels are in service in the U.S., Iran, India, Republic of Korea.

|

Chelyabinsk Tube-Rolling plant. Section of hydrostatic testing |

INVESTMENT BUSINESS PROJECTS

Participation of any company in national investment projects is quite important for evaluating its potential. Not many large producers of metals can boast of having such a program. That is why it is not difficult to imagine how much interest in Russia is being caused by the Alliance 1420 project. This joint project of UMC and Severstal JSC is aimed at forming a complex to produce pipes of 1420 mm in diameter for transporting oil and gas.

At present the demand of the Russian market for such pipes is met totally by import shipments from countries of Western Europe (65 %), Japan (25 %) and Ukraine (from 5 % to 10 %). The Alliance 1420 project is intended to change the situation in this market sector, especially so in view of expected increase of orders from Gazprom JSC. By experts’ estimates, in the nearest future the Russian gas monopoly will start laying new transcontinental pipelines and modernizing the existing gas transportation systems. All in all, Gazprom’s demand for pipes of 1420 mm in diameter will reach about 600,000 tons a year.

The project’s participants themselves, UMC and Severstal JSC, will provide investments of around $300 million needed to implement the project. This fact alone creates a special atmosphere of confidence in success. Since both partners do not doubt that their product will be competitive and that they do not need any additional guarantees (for example, from the State or a major foreign bank), the companies have already set a date, when the first lot of these Russian pipes are to be available. It will happen in 2004. Implementation of the Alliance 1420 project will allow Russia to get rid of its import dependence and become the fourth country in the world capable of producing such pipes. (For more details on the Alliance 1420 project see our story «Two projects for Gazprom» in Eurasian Metals, No.1, 2002).

As far as the development of UMC itself is concerned, another project is also quite important. It is aimed at forming a single steel-melting complex for all enterprises of the company. This complex should provide high-quality metal for production of railroad car wheels (steel for this purpose is still melted in open-hearth furnaces) and seamless pipes, production of which makes the company purchase about 150,000 tons of steel billets a year.

Under this project the Chusovskoy Iron and Steel Works (ChMZ) will get an electric steel-melting complex. Among its advantages are a convenient geographic location (at an equal distance from UMC’ leading plants), proximity to power sources, integration with the Gubakhinsky by-product coke plant, considerable resources of scrap in the area of its activity. All this promises a high economic efficiency of a new steel-melting complex.

In 2001 UMC’ enterprises manufactured about 1.5M tons of tube & pipe products, over 470,000 railroad car wheels, more than 20,000 tons of steel ingots, about 680,000 tons of pig iron, about 400,000 tons of rolled products, over 3,500 tons of ferrovanadium, about 40,000 tons of automotive springs.

Still one more investment project is to modernize production of railroad car wheels. UMC is planning to invest about $40 million in its implementation. This modernization should lead to production expansion and introduction of new technologies designed to provide railroad car wheels of new generation with very high wear resistance.

It is worth mentioning that the company has already reconstructed the Gubakhinsky by-product coke plant: an advanced coke-oven battery with the capacity of 650,000 tons of dry-quenched coke has been put in operation in 2002. The project costs around $15 million.

SALES GROWTH IN THE OFFING

The production and commercial activities of the United Metallurgical Company in the last two years prove its reputation as one of the most dynamic structures in the Russian metals industry. Growing volumes of production and profitability of sales with relatively low business risks testify to the professionalism of UMC’ managers as well as its engineering and technical personnel. Adapting the enterprises to requirements of today’s market, including certification of their products under international standards, allows the company to raise its competitiveness.

In the opinion of Andrei Komarov, favorable trends in the Russian economy are creating preconditions for increasing sales of UMC’ products in such sectors as construction, engineering, public utilities. As for marketing prospects in the most profitable direction, that is the oil-and-gas industry, the company has to reckon with not only a volatile market situation, which is determined by oil price fluctuations, but also with the extremely severe competition. However, UMC’ director general Anatoly Sedykh believes that the company’s positions are solid enough. In case of sales downfall in the domestic market UMC can increase its export shipments. The most promising markets are those in oil- and gas-producing countries of CIS (Azerbaijan, Kazakhstan, Turkmenistan) as well as markets in Syria, Iran, Algeria. Possible shipments of pipes to India and China are also being considered.

The experience of the United Metallurgical Company proves that there are corporations of international standards in Russian metals industry, which adhere to civilized principles and are capable of accomplishing long-term projects.

|

back

back