Izyaslav Peshkov

President of Elektrokabel Association, Dr. of Sc.(Eng.), Professor

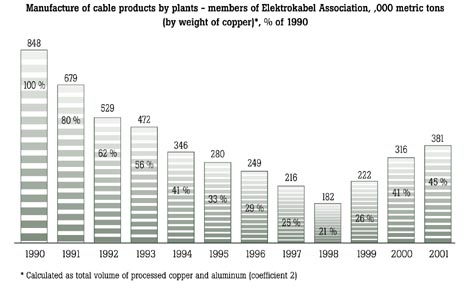

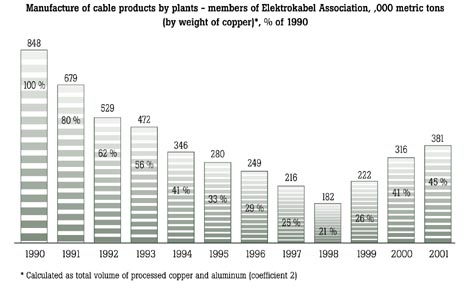

In the 1990s Russia decreased production of cable and wire. The depression was deepest in 1998 (see the figure) when the output of these items fell 4.7 times as compared with 1990. In 1998, 65,000 metric tons of copper and 36,000 tons of aluminum went to the cable industry. In 2001, these figures grew to 154,500 and 77,400 tons, respectively. Meanwhile Russian cable plants are able to consume up to 350,000 tons of Cu and 200,000 tons of Al every year.

Nowadays the cable industry is in dynamic progress. The output growth rates are ahead of the machinebuilding growth rates in general (Table 1).

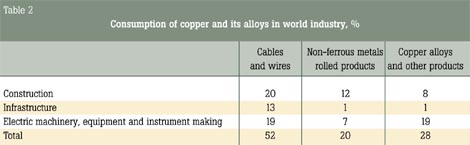

The Russian cable industry is the major copper consumer in the home market in line with the world practice (Table 2). At present 52 percent of copper totally produced worldwide are used for making cable products, and over 60 percent with waste remelting taken into account. A noticeable portion of copper is consumed in the making of non-ferrous metals rolled products for electrical engineering.

Copper can be aluminum alternate only in cables and wires for power industry. Aluminum consumed in the cable industry accounts for about 33 percent (by weight of processed metal). Here of special place are power cables and wires for aerial power lines.

The biggest Russian producers of cable items are enlisted below: copper processing – Elektrokabel Plant (Kolchugino, the Vladimir Region), Sibkabel (Tomsk), Moskabel (Moscow), Kamkabel (Perm), Podolskkabel (the Moscow Region); aluminum processing – Kirkabel (the Kirov Region), Irkutskkabel (Shelekhov, the Irkutsk Region), Saranskkabel (Mordovia), Moskabel, Kamkabel.

Izyaslav Peshkov

President of Elektrokabel Association, General Director of All-Russian Research Institute of Cable Industry (VNIIKP), Professor of Moscow Energy Institute. His scientific activities deal with electric insulation and cable engineering. Research courses in theory of reliability of cable products and wires and newest production technology, including innovations in optoelectronics, radiation and high-voltage engineering, have been carried out under his guidance. Author of more than 300 publications.

| |

| |

|

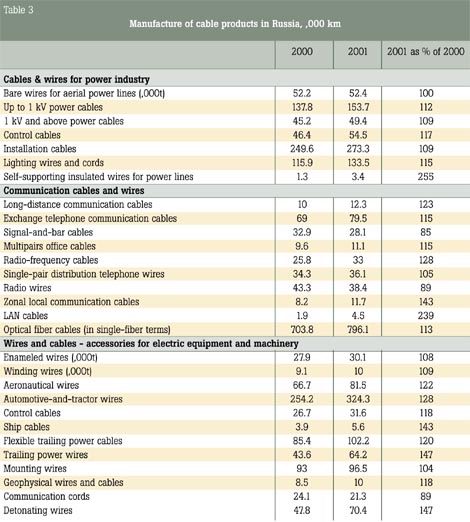

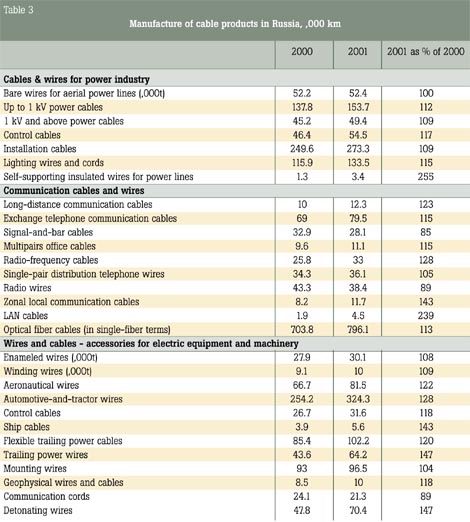

It is expedient to examine the main trends in the development of cable & wire production. Table 3 gives the data on the dynamics of production of main categories of cable products, among them:

– cables and wires for power industry (mostly, bare wires for power lines, power and control wires);

– cables of long-distance, exchange, zonal and office communication;

– cables and wires as accessories for electric equipment, machinery, ships, planes and other facilities (winding and enameled wires, flexible trailing cables, mounting, aeronautical, automotive-and-tractor wires, etc.).

Substantial growth of production of cables items for power industry is evident in Russia in the last two years. The output of impregnated paper-insulated power cables designed, for the most part, for underground 6-10 kV distributing mains, is still retained in Russia. The production of these items is predicted to go on for another 5 to 10 years but their service properties must be improved. The main ways of improving these cables are as follows:

– use of alternative lead sheath instead of aluminum one;

– application of multi-wire aluminum conductors instead of single-wire ones;

– improvement of impregnating compounds and impregnating process.

At present, medium-voltage cross-linked polyethylene-insulated cables are made only by ABB-Moskabel. Some Russian plants are taking measures on a set-up of production of 10-35 kV power cables, intending to install new facilities, in particular, continuous vulcanization lines.

Lately, production of copper-conductor power cables has been growing. In the case of aluminum used, conductor diameter increases which brings about larger consumption of insulating and protective materials. Power losses in aluminum conductors, especially, with long service life of cable taken into consideration, exceed those in copper conductors. Moreover, the mechanical strength of aluminum is much lower than that of copper, plus lower modulus of elasticity and higher heat expansion coefficient. Aluminum forms a non-conducting oxide film in open air. For this reason, further expansion of producing aluminum-conductor power cables is unlikely.

RAO United Power Systems of Russia (EES «Rossiya») took a decision on self-supporting insulated wires applied in low-voltage (0.4 kV) distributing mains and in 6-10 kV mains (if protected by insulation) to be used in aerial power lines. Current conductors of self-supporting insulated wires are made from Al or Al alloys. These wires, as compared with bare ones, have the following advantages:

– higher reliability due to much lesser probability of short circuit (phase conductors are insulated);

– resistance to environment influence;

– reduction of inductive impedance by 3.5 times which lowers power losses and increases load currents.

In 2001 the production of self-supporting wires grew 2.5 times.

Extended demand and larger production of these wires will involve set-up of new facilities at cable plants. The output of flame-resistant power cables, among them, PVC plastic-sheathed ones, will grow. The industry is in need of flame-resistant cables emanating no halogens whose compounds have a corrosive effect on electric and electronic facilities. This production started in 2001 will provide the requirements of nuclear power plants, above all. But the application field of this product is exclusively wide – conventional electric power stations, surface ships and submarines, airports, stadiums, cinema-and-concert halls, etc.

|

Tomsk. End products of Sibkabel JSC, leader of the cable industry |

An actual boom in the set-up of new communication (including TV) networks is taking place in Russia. Production of copper-conductor communication cables and wires grows at high pace but in future its level will stabilize while output will be added owing to optical-fiber cables. Not by chance their production in 2001 increased by

13 percent as against the previous year. Output of overhead optical cables in combination with ground-wire cables for power lines will be built up.

Copper will strengthen its place in the manufacture of computer LAN cables comprised of several twisted pairs with or without shield. These cables are applied for vertical storey wiring. Sometimes their world production used to increase at even higher pace than that of optical-fiber cables. In 2001 the Russian production of LAN cables increased 2.4 times.

Copper virtually has no alternate in winding wires, above all, enameled ones. In 2001 the Russian plants consumed around 40,000 tons of copper in the manufacture of winding cables – much less than a decade ago. However, while the world market for this product is static in Russia and other CIS countries the demand is growing because a revival of electric machine making takes place. That is, the forecast for the development of the Russian cable industry is fairly optimistic. It is the most dynamic market of non-ferrous metals for the time being.

|

back

back