Leonid Smirnov

General Director, State Research Centre of Russia «The Ural Institute of Metals», Corresponding Member of the Russian Academy of Sciences

Vanadium is in regular use in steel industry as an alloying element. Its main source is vanadium-bearing titanomagnetite and ilmenite-titanomagnetite ores. Russia has a world lead in vanadium reserves. The promising deposits of V-bearing ores are located in the Urals, Siberia, the Far East and in the North-West of Russia.

The registered reserves and probable resources of Uralian titanomagnetite ores are over 25 – 30bn metric tons where around 9m tons of vanadium are available. The Kachkanar ore complex presently under working has about 12bn tons of ore containing approximately 9m tons of vanadium. Sufficient V reserves are also present in the ores of the Kopansky, Medvedevsky, Syroyamsky and other deposits of South Ural. The Kopansky field contains 6bn tons where 0.4 % V2O3 are available. The titanomagnetite ore resources of the Suroyamsky deposit are in excess of 10bn tons of ore with around 0.1 % of vanadium oxides.

The Chineisky deposit of ilmenite-titanomagnetite ores located in the area of the Baikal-Amur railroad of East Siberia is one of the most promising fields. It ranks among the world biggest in probable iron-ore resources (about 30bn tons) while having no equal in the world in vanadium content (56m tons). One section of this deposit has been already prepared for working. A branch line from the Baikal-Amur railroad to this section is being laid.

|

Main Russian vanadium producers

– Kachkanar Vanadium Mine & Concentrator mines titanomagnetite ore and produces vanadium-containing iron-ore concentrate, pellets and sinter.

– Nizhny Tagil Iron & Steel Works (NTMK) converts Kachkanar sinter and pellets, makes vanadium iron and slag, as well as various steels, among them, vanadium ones.

– Chusovskoy Iron & Steel Works processes Kachkanar pelletized materials, produces vanadium iron and slag, vanadium pentoxide, ferrovanadium and different steels, among them, vanadium ones.

– Vanadium-Tulachermet JSC processes vanadium slag of NTMK make, produces vanadium pentoxide and ferrovanadium.

| |

| |

|

Petroleum incorporates a considerable portion of this metal. Fuel oil where one metric ton contains 80 – 150 gr V2O5 is its main heavy fraction. This product is also present in fuel oil-and-petroleum burning power plant ash.

Annual world output of vanadium as V2O5 and V2O3, together with FeV and other alloys as oxide processing products, accounts for 38,000 – 40,000 tons in terms of vanadium. This volume is recorded by world market. However, actual consumption, with due regard to this metal applied at the producers’, as intermediates (vanadium iron and slag along with screenings) as well as V-containing master alloys and ash fuel oil residues, greatly exceeds the above figures.

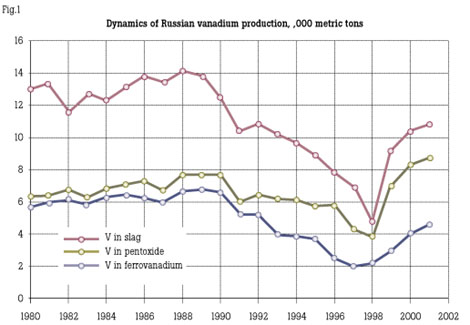

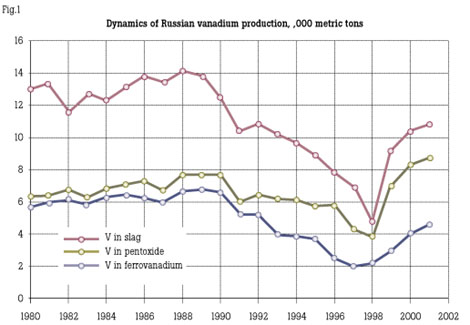

In Russia, the output of vanadium as V2O5 (primary vanadium, as named by VANITEC – International Technical Committee for Vanadium) was 7,800 per year in 1988-1990. At that time, the total world output equaled to 30,000 – 33,000 tpy of primary vanadium, Russia ranked second below South Africa. With the start of reforms in the Russian economy, the output of V-containing steels fell to a considerable extent, consequently, the production of primary vanadium used to drop. The BOF shop of the Nizhny Tagil Iron & Steel Works (NTMK), the main vanadium producer, was converted to a single-stage process of vanadium iron production , with a consequent lower V output in Russia and a sharp turnabout in world V prices.

In autumn, 1998 at NTMK the BOF shop resumed the duplex production of V iron and the output of prime V slag. Since 1999, Russia has been deliberately building up the production of primary vanadium.

In this country the greater share of V2O5 is made from vanadium slag melted at NTMK. EvrazHolding occupies the key position in the management of this works. Mainly due to the successful activities of this managing company, the Russian output of primary vanadium showed more than a two-fold increase for 1998-2001, reaching a record figure of almost 9,000 tons in 2001.

Future influence of EvrazHolding on the Russian and world markets may be greatly enhanced if the company sets up comprehensive processing of Chineisky titanomagnetites with vanadium recovered and made use of at Siberian works of its ownership – the Kuznetsk (KMK) and West-Siberian Iron & Steel Works (ZSMK).

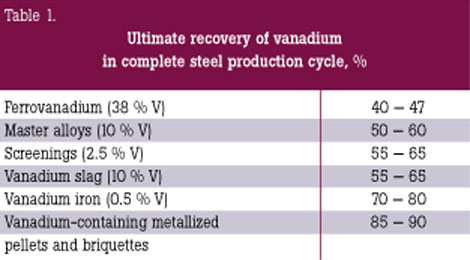

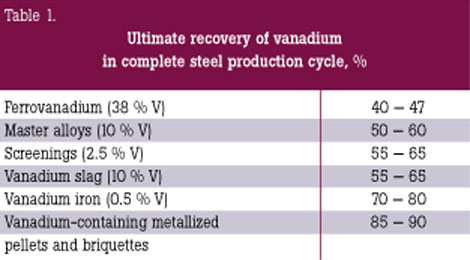

Ferrovanadium is the metal most frequently used in steel alloying. In Russia, the share of FeV (60 – 65 %) is the highest out of all V additives. But in this case the total recovery of vanadium is only 28 – 35 % from entry titanomagnetite ore to finished steel, and 40 – 47 % from concentrate to finished steel.

In order to reduce losses, the researchers and engineers of the Ural Institute of Metals developed process conditions of steel alloying with V iron and slag along with various V-containing master alloys made from V slag. It permits a noticeable increase in the total V recovery rate, thus reducing steel alloying costs.

An effect of vanadium on ordinary steel structure and properties has been studied at the institute. It was found that 0.05-0.2 % V introduced into a low-alloy steel ensured a 10-30 % higher strength in as-hot rolled-and-normalized and quenched-and-tempered states. A radically new technique of purposeful influence on steel structure and properties – carbonitride hardening – has been developed. It incorporates three simultaneous processes: hardening due to precipitation of finely-grained vanadium carbonitrides, refinement of steel grains and formation of perfect subgrain structure.

Very often, steel alloying with two or more carbide- and nitride-forming elements is optimal. The fact is that higher rise of steel strength is achieved when it is alloyed with

V (0.05-0.2 %), N (0.01-0.02 %) and Al (0.01-0.02 %) than with V alone. Alloying with two or three elements lowers steel sensitivity to brittle fracture. This is achieved in the case of alloying with V and Nb as well as V and Ti.

Leonid Smirnov

General Director of the Ural Institute of Metals, Corresponding Member of the Russian Academy of Sciences, Professor, Academician of the International Engineering Academy. Famous scientist in the field of comprehensive processing of natural alloy raw materials and production of high-quality steels of extended range, author of eight books, more than 550 articles and 230 inventions. Under his scientific guidance, research work in the directions enlisted below is under way:

– complex metallurgical processing of vanadium-containing titanomagnetite ores with production of steel, recovery and use of vanadium and titanium;

– supply of manganese to Russian steel and non-ferrous metals industries on the ground of native ore base and development of manganese-saving technologies;

– development of new steel grades and efficient methods of their production;

– development and putting-into-practice of highly-efficient technological processes and equipment for treatment of slag, sludge, dust and other waste of steel & non-ferrous metals industries.

Twice laureate of the State Premium of the USSR, laureate of the RF State Premium and the RF Government Premium in Science & Technology.

| |

| |

|

The technological basics of control of structure and properties of V-alloyed steels that were developed in the Ural Institute of Metals in complex with conventional strain-and-heat hardening made it possible to create a wide spectrum of steels with preset strength and ductility. Vanadium-containing low-alloyed steels showing high performance appeared. These grades are applied in usual climatic conditions while suitable for arctic service as well. The production flowsheet ensured good impact toughness even at minus 70oC.

Pipes for oil and gas mains are one main field of application for high-strength low-alloyed steels. In the years ahead, due to the construction of new pipelines and the necessity of repairs of existing ones, Russia will require about one million tons of these steel grades. Pipes of 1420 mm-dia. will be made at a new plant under construction in Nizhny Tagil.

|

Nizhny Tagil Iron & Steel Works. Railway wheels made from natural vanadium-alloy steel |

Up to 0.1 % V introduced into machinebuilding steels provides for a 10-20 % higher strength. Steels for transport application (for rails, wheels, tires) can be effectively alloyed with vanadium. At present NTMK produces approximately 300,000 tpy of rails and wheels from vanadium steel. The testing and service trials of heat-hardened rails from steel deoxidized with FeSiCaV alloy showed that their life and reliability in service are 1.25 and 1.22 time better than for rails from non-vanadium steels. In testing trials with freight train, vanadium steel wheels show wear resistance 13-17 % higher than for non-vanadium steel wheels.

It seems very promising to apply vanadium steels in automotive industry. Springs from these steels have 10-30 % longer life as against non-vanadium steels, due to higher fatigue strength.

Cheap techniques of alloying with BOF slag and screenings opened up the way to wide application of vanadium in casting steels. Parts made from such steels have better wear resistance, with 10-15 % lighter weight of castings. The steels are successfully used in the manufacture of railroad cars, power-generating and agricultural equipment.

Nowadays world production of V-microalloyed high-strength steels is estimated at 5-7 % of total steel output. According to the data of VANITEC, this value will grow to 20 % with time. It will happen by virtue of wider application of similar steels. For example, in Russia orders for vanadium steels for boilers, oil & gas pipeline tubes and pipes, rails and wheels as well as for other high-strength products grow in numbers. Larger production of V-containing low-alloyed steels is a very promising trend of development of the Russian steel industry, thus providing better performance and lower steel consumption. For this purpose, Russia has adequate vanadium resources, advanced alloying technologies, a large number of vanadium-containing steel grades developed and put into practice.

|

back

back