|

| Magazine |

|

| About |

|

| SUMMIT |

|

| Contacts |

|

| Home |

|

|

|

|

|

| |

|

|

|

| #5' 2003 |

print version |

|

|

SAKHALIN-2: PREFERENCE IS GIVEN TO RUSSIAN PIPES |

|

Vladimir Shlyomin

The United Metallurgical Company (UMC) and Severstal Group won a major tender connected with Sakhalin-2, one of the most prestigious projects to construct oil-and-gas pipelines. This was reported recently by the Sakhalin Energy Investment Company Ltd. Signing contracts took place after this company announced the final decision of placing orders for pipes to be used in construction of onshore and marine pipelines under the program of the second stage of implementing Sakhalin’s project.

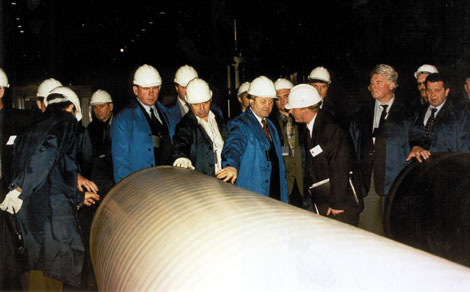

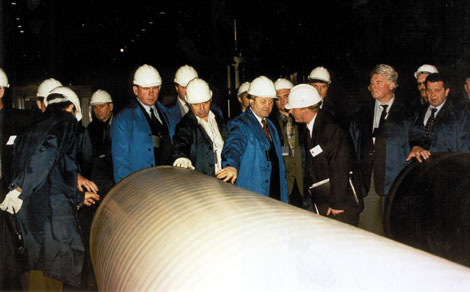

After getting acquainted with the production facilities at VMZ, deputy chairman of the board of management Alexander Ananenkov confirmed Gazprom’s intention to reduce import shipments of large-diameter pipes |

o far Sakhalin-2 is the only project in Russia with 100 % of foreign investments, which is based on the Production Sharing Agreement (PSA). It provides for developing two fields on Russia’s shelf near the Sakhalin Island in the Sea of Okhotsk.

The first one, the Piltun Astokhskoye (PA) field, has considerable oil reserves and some reserves of associated gas.

The second one, the Lunskoye field, on the contrary, contains large reserves of gas and some reserves of oil.

Both fields are located about 15 km from the north-eastern coast of Sakhalin in the offshore area that is usually covered with ice for 6 months a year.

Just two or three years ago oil and gas companies never turned to Russian pipe producers with requests to do works of this kind. Traditionally, suppliers of pipes with the diameters from 20 to 48 inches (from 550 to 1,200 mm) were German, Japanese and Italian companies. But now the situation starts changing radically.

Among enterprises of CIS member countries the UMC-owned Vyksa Steel Works became the first one, which received an important order from the Sakhalin-2 international consortium led by Royal Dutch/Shell. As a result of the technical audit, the quality of its products and technologies was recognized as being completely in conformity with the project’s requirements. The Vyksa Steel Works is to produce 45,000 tons of pipes with protective coating for about $36M. Over 2,000 employees of the enterprise will take part in fulfilling the contract.

The Vyksa Steel Works (VMZ) has already had a positive experience of participating in projects on the Sakhalin Island. It won three tenders under the Sakhalin-1 project and was chosen as the only appropriate supplier of trunk pipes by Exxon Neftegaz, the operator of this project. Under that contract VMZ should make pipes with the diameter of 610 mm designed for the working pressure of 120 atm. Never before such pipes for trunk pipelines were produced in Russia: the maximum working pressure level stood at 85 atm. The opportunity to meet requirements of Exxon Neftegas was the result of VMZ’s large-scale production modernization being implemented by the United Metallurgical Company (UMC). And the contract with Exxon Neftegas became an additional incentive to accelerate its completion.

VMZ is Russia’s largest supplier of straight-line-seam single-weld pipes for trunk pipelines. Its production modernization is aimed at making it possible to produce the entire range of pipes requested by Russian as well as foreign oil and gas companies. Even now VMZ is already making the whole number of dimension-type pipes according to the API and ISO standards. By the end of 2003 it will expand their output and start producing pipes with the diameter of 1,067mm. A year later they will be followed by pipes with the diameter of 1220 mm to1420mm and wall thickness of up to 40 mm. This is the largest project of the United Metallurgical Company, which is investing no less than $100M in it.

The modernization of pipe-forming mills, introduction of the modern welding control laser system and the latest system of ultrasonic non-destructive check after hydraulic testing, which secured the high quality of the welding seam and a 100 %-contol, allowed the enterprise’s specialists to briskly get down to carrying out the order of Exxon Neftegas.

In May 2003 VMZ produced a batch of trial pipes, which underwent a complex checking with the use of experimental resources of the institute VNIIGAZ, the scientific research division of the company Gazprom. The opinion of VNIIGAZ was definitely positive: by their technical characteristics VMZ’s pipes were even better than required by the contract. For example, they can be used with the working pressure of up to 125 atm., with temperatures during construction works of up to –60oC and up to –12oC during operation.

In late July the first batch of pipes for Exxon Neftegas was shipped to the Sakhalin Island. The international experts, who were receiving them, stated that these products were meeting all the requirements of the customer.

"The production of pipes with so high characteristics by VMZ is a very important event. It can change the attitude toward Russian producers", points out Alexander Samoilov, the director of the Pipe Industry Development Foundation. In his words, the very fact of the serial production of pipes designed for the working pressure of 125 atm., proves the compliance of domestic products with the market’s highest requirements and it should open up new prospects for Russian pipe makers.

The demand for high-strength pipes is only stimulated by the expansion of oil and gas production in sever climatic conditions, on the sea shelf, and by ever-toughening requirements with respect to the ecological safety. The ability to produce pipes with such characteristics is becoming a necessary condition of being competitive for any pipe-making company.

This was proved by the victory of VMZ at the tender concerning the Sakhalin-2 project, when UMC became the only Russian company, which withstood the rivalry with respect to suggested parameters of pipes and prices and which took the upper hand over such well-known producers as Japan’s Metal One.

The selection of VMZ made by the Sakhalin-2 consortium may be considered a turning point in its attitude toward Russian producers. Jaap Guyt, the manager of the project to construct the pipeline, points out that pipes for this project are Russia’s new kind of products, which are subject to high technical requirements. That is why their production is not an easy task for Russian enterprises. "The level of competition between Russian and foreign companies so as to get contracts was quite high. In this connection it is a great pleasure to note the important role of the Vyksa Steel Works in supplying pipes", he says.

President of UMC Anatoly Sedykh, when commenting on the victory of his company at the Sakhalin-2 tender, said the following:

|

In four production seasons during shipping periods since 1999 (from June to December) the output of high-quality oil on the Sakhalin Island exceeded 5.3 million tons. In 2002 the Sakhalin Energy Investment Company Ltd. produced and exported 1.46 million tons of oil. |

|

"The concern Shell, the leader of the Sakhalin-2 consortium, is known for the very strict requirements to those companies, which are fulfilling its orders. And in this case the requirements were particularly high due to the conditions of operating the oil pipeline, which should ensure the region’s ecological safety. The selection of UMC to be a supplier of trunk pipes means the greatest rating of VMZ’ s specialists and the reconstruction of our pipe production, which is becoming one of the world’s leaders. We are very proud of this recognition".

UMC shares this success with the company Severstal, its permanent partner, which supplies strip for welded pipes. Together with VMZ it is developing promising steel grades. In 2003 they perfected the technology of rolled stock production at mill-200 and mill-2800 for pipes with the diameters of 20 and 24 inches. Pipelines of the Sakhalin-1 and Sakhalin-2 projects will be laid down in seismically dangerous regions and that is why requirements to them are particularly strict. Severstal and VMZ mastered production of steel of the L450MC grade according to the ISO standard specially for the Sakhalin projects. Steel of the X65 strength grade according to the API standard is similar to it.

To a large extent Sevestal’s investment program is oriented on improving quality and increasing volumes of pipe production. To this end important improvements were made in the production technology. For example, the cast iron desulfurization plant is being put in operation, which will make it possible to produce low-sulfur grades of steel having high corrosion resistance. Mill-500 is being modernized: a sheet-straightening machine to provide quality characteristics of strip with respect to plottines as well as a controlled cooling installation are now operational.

"It goes without saying that it is important to us to participate in one of Russia’s largest oil-and-gas projects", said Dmitry Goroshkov, the sales director of Severstal JSC. He also stressed that today Severstal is recognized among foreign and Russian suppliers as the only company, which during the audit "was found in complete compliance with conditions of the tender for constructing pipelines".

Sakhalin-2 is one of the world’ largest pipeline projects. In order to gather and bring to the shore hydrocarbons produced with a help of sea platforms it provides for constructing pipelines with the total length of about 167 km. Besides, it is planned to construct oil and gas pipelines in one corridor with the total length of 1,600 km to transport hydrocarbons further to a liquefied gas plant and oil terminal that will be built in Sakhalin’s south. The volume of orders, tight schedules of products’ supplies for construction of pipelines (the oil pipeline construction is to be completed in 2005 and the gas pipeline should be ready for operation in 2006), technical requirements to sea pipelines as well as to the high-pressure gas pipeline illustrate the complexity of the existing tasks. Such large contracts are rarely fulfilled in one country. And Russia is no exception.

|

|

The total explored recoverable reserves of oil and condensate are agreed to stand at 140 million tons (4 billion barrels) while reserves of natural gas amounts to 550 billion cubic meters.

The project’s shareholders: Shell Sakhalin Holdings B.V. with 55 % (Royal Dutch/Shell is the founding company), Mitsui Sakhalin Holdings B.V. with 25 % (the founding company is Mitsui & Co., Ltd. ) and Diamond Gas Sakhalin B.V. with 20 % (the founding company is the Mitsubishi Corporation).

According to the complex plan approved by the Supervisory Council, over $8B should be invested in the project. It is planned to install two sea platforms, to construct an onshore technological complex for gas and condensate treatment in the north of Sakhalin as well as to lay down two 850 km-long pipelines. The most important component of the project is a plant to be constructed that will have two technological lines of natural gas liquefaction with the annual production volume of 4.8 million tons each. This plant will be located near terminals in the southern part of the Sakhalin Island, where the sea does not freeze the whole year round. The start-up of shipping the first batches of liquefied gas is planned for the second half of 2007. The all-the-year-round production of oil will begin in 2006.

When the project’s design capacity is reached, the annual production of oil and condensate under Sakhalin-2 will amount to 8.5 million tons, the volume of gas production will come to 19 billion cubic meters a year.

|

| |

|

Jaap Guyt, the manager of the project to construct oil and gas pipelines said: "In order to implement a major international project enormous supplies of pipe products are required. We have divided the order in lesser parts because this will make it easier to do the management".

The biggest portion of pipes will be produced by the Japanese corporation Metal Wan, which received the order for $280M. It is to make pipes with the total length of 900 km that will bring gas from Sakhalin’s north to its south. The Russian-Japanese consortium set up by Mitsui & Co. and UMC will supply pipes for a 740 km-long oil pipeline. Thus, the Sakhalin projects are becoming one of the most impressive markets for leading pipe-making companies.

|

|

|

|

|

|

current issue

previous issue

russian issue

|

|

back

back